THE INTRODUCTION OF LIQUID A KIT WITH NANO7™

Features

Upgrade Your Motorcycle Suspension with Liquid A Kit

Welcome to Liquid A Kit! We provide the ultimate solution for motorcycle riders looking to enhance their suspension performance and reduce maintenance costs.

Premium Quality Fork Seals

Our Liquid A Kit Fork Seals are crafted from top-quality materials, including advanced polymers and a specially formulated NBR rubber compound. These components ensure superior durability and performance. The low-friction design of our fork seals minimizes stiction, resulting in a smoother and more responsive suspension system, capable of handling the toughest riding conditions.

Boost Performance with NANO7™ Additive

For even greater performance gains, use our Liquid A Kit Fork Seals with the NANO7™ additive.

NANO7™ Low Friction Additive

- Compatibility: Suitable for forks or shocks with NBR rubber seals and fork oils.

- Mixing Instructions: Add one pillow pack of Nano7 (15ML) to one quart of your preferred suspension fluid. This mixture works for both cartridge and outer oil volume ‘telescopic suspension chambers.’

Benefits of NANO7™ Additive

- Nano-Sized Slip Particles: Provides anti-wear and low friction benefits across all internal fork parts and oil seals.

- Functions: Extreme pressure additive, anti-wear agent.

- Compatibility: Works with all suspension fluids compatible with NBR rubber seals (Mineral-Based Group I, Group II, and Group III).

- Features: Easy incorporation, improved anti-wear, non-stick properties, and low friction.

Commitment to Quality

At Liquid A Kit, we are dedicated to providing the highest quality products and exceptional customer service. We stand behind our products with a satisfaction guarantee and are always available to answer any questions you may have.

Order Now

Upgrade your motorcycle’s fork performance and reduce maintenance costs with Liquid A Kit Fork Seals and Nano7 oil additive.

To order Call (831) 588-6720

Kit seal sizes available – 48mm and 49mm MSRP: $72.50 USD

Are all fork seals the same?

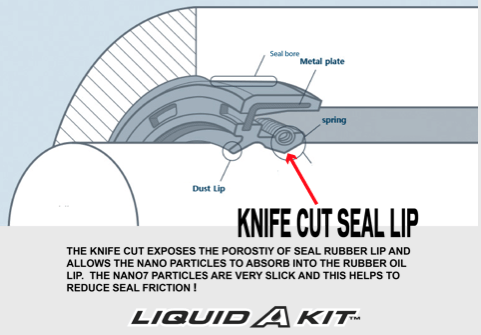

No they are not. Liquid A Kit fork seals have a precision knife cut oil lip. Using this method of manufacturing we get a sharp sealing lip. When we knife cut the seal lip, it exposes the micro pores of the rubber. With the pores of the rubber exposed, the Nano7 slip particles infuse into the seal lip rubber to further reduce slide friction. Our low friction fork seal kits offer leading edge technology and are engineered to be long lasting.

Click here for fork seal installation PDF file:https://clicksuspension.com/wp-content/uploads/2023/02/48mm-fork-seal-installaiton_rev2.pdf

Or you can play the fork seal installation video below.

Copyright © 2016 Click Suspension Labs all rights reserved. Click Suspension Labs, Click Suspension,Liquid A kit,Nano7 and Slip Particle Technology are trademarks held by Click Suspension Labs.