Collapsed WP AER48 forks

Why Does My WP AER48 Fork Collapse or Get Stuck Down?

This page addresses the common question: why does my WP AER48 fork collapse or get stuck down? Although this issue is rare in my workshop, I have encountered a few cases. In one instance, a dealer reported this problem with a brand new bike straight out of the crate. It’s challenging to determine how widespread this issue is, as there are no public reports from WP.

Understanding the WP AER48 Fork Collapse Issue

Some WP AER48 forks experience a problem known as collapsing or getting stuck down. This occurs when excessive air pressure moves into the negative pressure chamber, causing the fork to collapse. This issue is well-known in the bicycle suspension industry and is often mentioned in bicycle suspension owner’s manuals under cautionary sections.

Innovative Design of the WP AER48 Fork

The WP AER48 fork uses an innovative approach by incorporating the concept of the air negative spring chamber air bypass channel. This idea is detailed in patent #6,135,434 by another suspension company I previously worked for. WP’s application of this concept, originally patented for rear shocks, is a brilliant move. It creates a simple, user-friendly negative air spring.

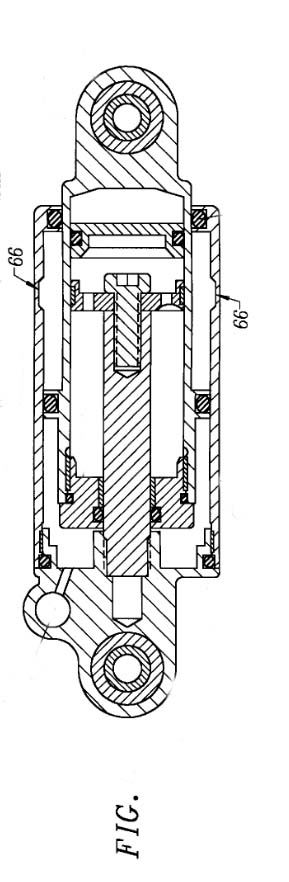

Drawing for patent # 6,135,435 Channel port ID#66

Exploring Negative Springs in Motocross Suspension Systems

The use of negative springs in motocross suspension systems dates back to the 1970s, pioneered by Steve Simmons and Bob Fox. This innovative approach has evolved over the years, impacting the design and functionality of modern suspension systems.

Common Causes of Air Fork Collapse

Several factors can cause an air fork to collapse. The most common issues include:

- Seal Defects: Faulty seals can lead to air pressure problems.

- Debris Under the Seal Lip: Dirt and debris can compromise the seal’s integrity.

- Dither Mode: A term I coined in 1997, refers to a specific failure mode in cold weather conditions.

Discovering Cold Weather Issues with NBR Seals

During my early years of bicycle air spring testing, I discovered that NBR seals fail in cold weather. I clearly remember demonstrating this issue to the engineering team. Cold temperatures caused the seal material to lose elasticity, leading to air pressure bypass and air spring collapse.

The rubber seal lip must be flexible and resilient to maintain contact with the air piston cylinder bore. You can test an O-ring’s elasticity yourself:

- Flex an O-ring into a figure eight at room temperature and observe how it snaps back.

- Freeze the O-ring for about 15 minutes and repeat the test. The O-ring will be much slower to return to its original shape, unless it is made from cold weather-rated material.

A Lesson from the Space Shuttle Challenger Accident

The 1986 Challenger disaster was caused by the failure of O-ring seals that weren’t designed for the unusually cold conditions at launch. This incident underscores the importance of using properly rated materials for seals in all conditions.

Here are a few ways to get fork back to ride height before taking the air side cartridge apart to service.

Caution ! : Procedures may be used to Un-collapse the WP AER48 fork. Use at your your own risk. Riding dirt bikes are dangerous and put you at risk of death or serious harm.

#1

Follow WP fork service manual and procedures to service the WP AER 48 fork.

#2

Pump the fork up to 250-300 PSI and try to pull the fork up to ride height by holding front wheel down and having your buddies pull up on handle bars. If this method work’s make sure to re-set your fork air pressure.

#3

We suggest that you always have the fork inspected / serviced by qualified technician as soon as possible.